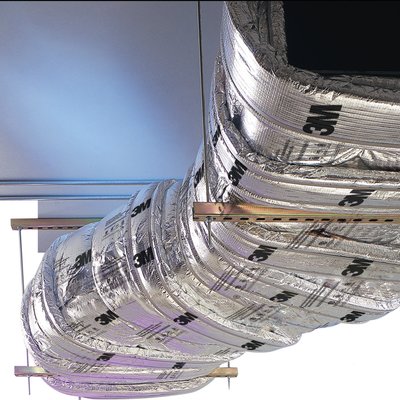

Grease duct installation techniques 3m fire barrier duct wrap 615 should be installed per the application design listing in accordance with the following basic installation instructions.

Grease duct fire wrap code.

Foil encapsulated ceramic blanket such as unifrax s fyrewrap elite 1 5 or 3m s fire barrier 615 both industry leaders.

Material and equipment 24 or 48 wide by 1 1 2 38 1mm thick by 25 ft.

Installed as a two layer system fyrewrap elite 1 5 complies with the international mechanical code imc and uniform mechanical code umc.

We know which product to use.

Fyrewrap elite 1 5 duct insulation is tested per astm e2336 and is acceptable as an alternate to a traditional fire rated shaft.

3m fire barrier duct wrap 615 is manufactured with a man made vitreous spun.

It is flexible and lightweight for easy installation and passes the necessary fire tests to achieve two hour fire resistance requirements.

On site welded grease ducts must be wrapped in two layers of insulation tested to ul 2221 standards at the construction site ul 2221 classifi ed prefabricated stainless steel grease ducts no longer have to be contained in a fi re rated shaft.

Such grease duct systems and exhaust equipment shall have a clearance to combustible construction of not less than 18 inches 457 mm and shall have a clearance to noncombustible construction and gypsum wallboard.

Grease ducts constructed in accordance with section 506 3 1 shall be permitted to be enclosed in accordance with the international building code requirements for shaft construction.

The primary impact the code changes may have on grease duct selection is cost differentiation.

3m fire barrier duct wrap 615 is the only fire rated duct wrap product you ll need to help protect grease and air ducts.